Steel Structure

Structural steel is steel construction material, a profile formed with specific shape or cross-section and certain standards of chemical compositions and mechanical properties.

Structural steel differs from concrete in its attributed compressive strength as well as tensile strength. High strength, stiffness, toughness and ductile properties of structural steelare the reason for popularity of steel structure in today’s commercial and industrial building constructions. It can be developed into nearly any shape, which are either bolted or welded together in construction and can be erected as soon as the materials are delivered in site. These steels are painted providing water resistance and are enveloped with fire resistance material in order to prevent them from lifetime corrosion and to intact their tensile strength and stiffness.

Hence, in modern day construction, the tallest structures today (commonly called “skyscrapers”) are constructed using structural steel due to its constructability, as well as its high strength-to-weight ratio as compared to concrete based structure.

For Design &construction of critical & sophisticated steel structureHimalayan Steel & Alternative Construction collaborate with Mcdonald Steel Building Product, Bangladesh Website- www.mcdonaldsteelbd.com.

Structural steel differs from concrete in its attributed compressive strength as well as tensile strength. High strength, stiffness, toughness and ductile properties of structural steelare the reason for popularity of steel structure in today’s commercial and industrial building constructions. It can be developed into nearly any shape, which are either bolted or welded together in construction and can be erected as soon as the materials are delivered in site. These steels are painted providing water resistance and are enveloped with fire resistance material in order to prevent them from lifetime corrosion and to intact their tensile strength and stiffness.

Hence, in modern day construction, the tallest structures today (commonly called “skyscrapers”) are constructed using structural steel due to its constructability, as well as its high strength-to-weight ratio as compared to concrete based structure.

For Design &construction of critical & sophisticated steel structureHimalayan Steel & Alternative Construction collaborate with Mcdonald Steel Building Product, Bangladesh Website- www.mcdonaldsteelbd.com.

Advantages of steel structures

Speed of Construction

Structural steel enhances construction productivity because of its shop fabrication while maintaining tight construction tolerances. Field placed material will always lag behind the productivity curve. Productivity enhancements for construction will occur not in labor-based field activities, but inshop-based technology enhancements.

Quality Control

With latest computer software for design and detailing of pre-engineered and structural steel buildings, Himalayan steel & alternative construction guarantees competitive designs and highest quality drawings which ensure faster construction at site.

Strength in delivery and erection of steel structures

Himalayan steel & alternative construction has capacity to supply and construct structural steel buildings for any type of projects such as power plants, steel mills, sky scrapers, bridge, office buildings etc.

Consistent product quality

We use high quality steel structures with high compressive strength as well as tensile strength to ensure consistent product quality. Zincalume and color bond steel are also used as the ingredient materials for roofing and wall cladding application which ensures high product quality.

Safety measures

Safety is a prime focus of Himalayan Steel & Alternative Construction. We use steel structure which follows accepted industry standard safety measures in accordance with NBC114 Construction Safety.

Loading & Design Criteria

Minimum Imposed (Occupancy) Load, Wind Load, Seismic design & Snow load, as per NBC 103, 104,105& 106 respectively. But we generally prefer codes/guidelines provided by AISC (American Institute of Steel Construction) for design criteria.

Cost competitiveness and flexibility

Design flexibility, quality cost control, effective mobilization of human resources help us to minimize wastes. Hence, costs are relatively lesser working with Himalayan Prefab. We are flexible enough to architect a design layout according to the customer’s wish. We design layout which can be highly adaptable for future expansion.

Modifiable

Structural steel buildings can be modified in the future for new applications, loading conditions, vertical expansions and changes in owner desires in ways that other framing systems can never accomplish.

Ease of Design

Structural steel remains the most desirable material for the structural engineer to design in. tools for structural steel design abound and are a quantum step ahead of tools for other systems. Full integration between analysis, design, detailing and fabricating software is in use today. The structural steel industry is the poster child for collaborative Building information modelling.

Foundations and Seismic resistance

Prefabricated steel structures have simple designs which are easy to construct and are light- weight in nature. Hence, simple foundation work is required to hold the structure from the base. Due to their low-weight flexible frames, theyoffer higher resistance to seismic resistance.

Eesthetic Appeal

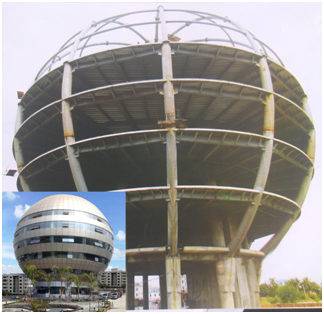

Structural steel allows the project architect a greater degree of expression and creativity in their design than any other construction materials as they address both the functional demands of the building and unique identity of their client. Architects praise the natural beauty of steel and are excited about exposing it is the design of their structure to emphasize grace, slenderness, strength and transparency of frame.

Innovative

The structural steel industry continues to pioneer new innovations for both the material and the use if structural steel. The migration of the material specification for hot rolled structural sections from A36 to A992 has increased the yield stress or strength of material by 40% from 250 mpa to 345 mpa.

Design Flexibility

From the simplest, functional structure to the complex, signature design structural steel can be readily used to accomplish the design intent of the architect and structural engineer. No other framing material comes close to structural steel in the ability to encourage freedom of expression and design creativity.

Structural Components

- Built-up Members (Column, Beam etc.) High grade steel plate conforming to ASTM A572 grade 50. Factory painted with a minimum of 35 microns (DFT) of red oxide primer.

-

Purlin and Girt

High grade steel conforming to ASTM A607 grade 40/50 Factory painted with a minimum of 35 microns (DFT) of red oxide primer or Galvanized, coating mass 180-275 GSM. Available in 1.5mm, 1.75mm, 2.0mm, 2.25mm, 2.5mm and 3.0mm thicknesses. -

Bracing

Cable bracing is shown. Other bracing systems are available at the option of McDonald Steel’s engineering department. Cable is manufactured in accordance with ASTM A475 extra high strength galvanized strands. - Mezzanine Deck Panels

- High Strength Bolts

- Fastener

- Trimek HI-Ten Steel Roofing Profile

|

Application of Steel Structure:

|

Our Services

|