t-type

why T-type

- Short construction period: Steel structure, wall and roof components can be easily and quickly assembled and disassembled; 4 people can assemble such a house at the size of 150 sqm in 2 days.

- Durable: The house can be disassembled and assembled more than 8 times, and normally used for more than 20 years.

- These materials are waterproof, fireproof, windproof, sound insulating and heat insulating; Earthquake proofing grade is 7 grade.

- Its packaging can save much space in transportation, this means much cost is saved for clients.

- A new environment friendly concept, it meets all the requirements of environment protection.

Material used Prefabricated Structure:

Roof Options:

- PUF Corrugated Panel

- EPS Corrugated Panel

- CGI sheets

- UPVC roof

- Asphalt shingles

Wall Options:

- PUF Sandwich Panel

- EPS Sandwich Panel

- Solid Cement wall Panel

- Dry Wall System

- AAC Blocks

- Different claddings/siding materials.

EPS and PUF Panel:

Expanded Polystyrene (EPS) Panel

The EPS sandwich panels shall be made out Pre coated steel (PPGI) sheet on both side of EPS (Expanded Polystyrene foam). Expanded Polystyrene is a lightweight closed cell rigid insulation formed by the expansion of polystyrene beads. It has excellent long term thermal and moisture resistance. EPS insulation is reliable, cost effective and compatible with major construction materials. The wall panels will have tongue & Groove arrangement joint system.

PPGI sheet & insulations are bonded with high intension adhesive at high temperature and pressure through auto forming machine. They have excellent long term thermal and moisture resistance, which are reliable, cost effective and compatible with major construction materials.

Thickness availability:

40mm, 50mm, 75mm, 100mm, 125mm, 150mm, 175mm, 200mm.

EPS Panel

PUF Panel

Expanded Polystyrene (EPS) Panel

- Pre-engineered and factory made for precision.

- Internationally accepted and meets or exceeds all building code specifications.

- Higher energy savings due to very low thermal conductivity.

- Flexibility in design and choosing various option on fascia of panels and colors.

- All weather proof construction and maintenance free.

- Long lasting value with controlled quality, accuracy & speed of construction and caters for better functionality and application.

- Easy Relocation.

Cement Panel:

Cement sandwich panel is a strong and highly durable material and a good choice in both commercial and multistory residential applications it is a series of building material with fly ash, expanded polystyrene beads and sand compound as core material. Insulated cement sandwich panels combine the strength and durability of concrete with the unmatched insulating capabilities of Styrofoam extruded polystyrene. Styrofoam’s closed cell, moisture resistant structure provides dependable and predictable performance, even under the harsh conditions.

Thickness availability:

50mm, 60mm, 75mm, 90mm, 100 mm, 120mm, 150mm, 180mm & 210mm.

Cement Panel with EPS Bead

Cement Panel with EPS Bead

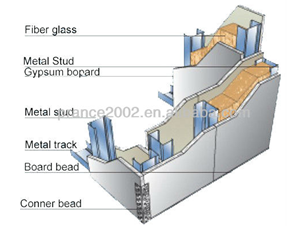

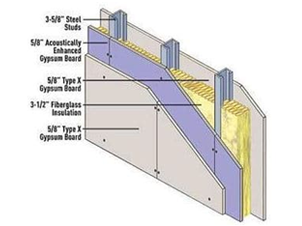

Dry Wall System:

This system is made of durable galvanized steel, which usually uses Fiber cement board, MGO Board calcium silicate board as surface material. Compared with wooden board/gypsum board can provides safer and resistive wall. Besides that, compared with bulky brick wall, it can greatly reduce the weight of building. In this system, thermal and acoustic insulation product can also be filled in partition frame to create a safe and quiet environment.

Thickness availability:

50mm, 60mm, 75mm, 90mm, 120mm, 150mm, 180mm & 210mm.

AAC Block:

Autoclaved aerated concrete (AAC) is a lightweight, precast, foam concrete building material suitable for producing concrete masonry unit (CMU) like blocks, Composed of quartz sand, calcined gypsum, lime, cement, water and aluminum powder. AAC products are used for both interior and exterior construction, and painted or coated with a stucco or plaster. In addition to their quick and easy installation, ACC materials can be routed, sanded, or cut to size on site using standard power tools with carbon steel cutters.

Size of Block are 600×200 and Thickness varies 75 to 300 mm.